Breaking: The recently-launched Massivit 10000 additive manufacturing system and its novel casting material have been selected as finalists by Composites industry authorities for two separate awards… once again!

The ACE Awards

If you haven’t heard of it, the Awards for Composites Excellence (ACE) is an annual, prestigious industry competition for composites. It recognizes “outstanding achievement and innovation in technology, manufacturing and product development.”

Hosted by the American Composites Manufacturers Association (ACMA), the ACE awards are a big deal for anyone in the composites industry. Divided into three categories, a total of five awards will be presented to winners at the upcoming annual CAMX [Composites and Advanced Materials] Expo.

Second Time Running!

If all of this sounds like deja vu, that’s because Massivit actually won the 2021 ACE Award for Composites Excellence just last year, in the category of Manufacturing: Equipment And Tooling Innovation!

This year we’re up for the 2022 ACE Award for the new CIM 500 casting material in the category of Manufacturing: Material and Process Innovation.

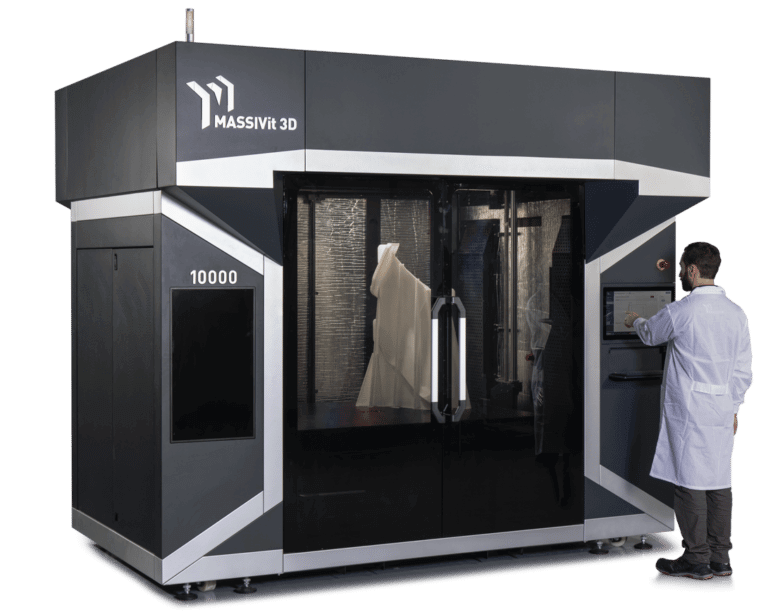

That’s not all.. we’ve also been nominated for the CAMX Award for Unsurpassed Innovation for the Massivit 10000 – which offers automated mold production for composites with advanced AM.

The First Ever 3D-Printed Isotropic Molds

One of the most unique features about CIM 500 casting material is its ability to produce 3D-printed, isotropic molds.

Most additive manufacturing tooling systems utilize thermoplastic materials that are extruded as layers which cool with varying time intervals, resulting in a porous, incomplete interface between layers as well as a lack of molecular bonds between layers. This results in anisotropic molds. In addition, these molds are prone to expand in an inconsistent manner in heated conditions due to uneven adhesion between layers.

Cast In Motion (CIM) is the world’s first additive manufacturing technology to enable true isotropic molds. CIM 500 casting material is a high-performance, thermoset, epoxy-based casting material that forms fully cross-linked molecular bonds between casting intervals, producing a uniform cast. This ensures consistent mechanical and thermal properties across all axes, especially in heated environments. CIM 500 also offers a low and consistent thermal expansion (CTE) at high temperatures. It provides high thermal stability (HDT) up to 145 degrees Celsius.

Molders across a range of industries can now digitally “print the unprintable” using CIM 500 in conjunction with Massivit’s Cast In Motion technology. From open and closed molds to wash-away mandrels, tools, jigs and fixtures, mold production no longer has to pose as a bottle neck to manufacturers of composite components.

See You at CAMX 2022!

If you’re planning to rock up at the CAMX Show – in the Anaheim Convention Center October 17-20 – be sure to join us at the awards presentations!

We’d also love to catch you there at Booth #48 to talk about our award-winning technology and show you the Massivit 10000 in person! Contact us with any questions here.