More print service providers and fabricators for scenic environments, entertainment, and exhibitions are turning to large format 3D printers either as a supplement to their CNC production, or as a replacement entirely. There are many ways we can look at a side-by-side comparison of a 3D printer and CNC router, and below we’re going to focus on the key areas where we see a difference between the two.

3D Takes a Big Jump

One of the issues that always came up with regard to 3D printing is size. Size limitations used to be the end of the argument when comparing 3D printing to CNC. This is no longer the case, as large format 3D printers have gotten bigger, and more capable of producing huge results. The Massivit 1800, for example, can print parts up to 1.8 meters (6 feet) tall. That’s large in its own right, but the size potential is limitless when you bond parts together.

A great example of this is the Rugby World Cup, where digital print shop, Composite Images, leveraged their Massivit 1800 3D printer to create 2.4 meter tall rugby players. Dubbed the League of Giants, this sports event campaign was a smashing success as passersby couldn’t help but take notice of the massive display. Due to the fact that they were produced hollow, these props were easily internally lit to create an alluring nighttime attraction as well.

3D Wins The Race, Hands Down

Although CNC routers have improved over the decades when it comes to speed, for any project with the least bit of complexity, they are no match when compared to a top quality large format 3D printer.

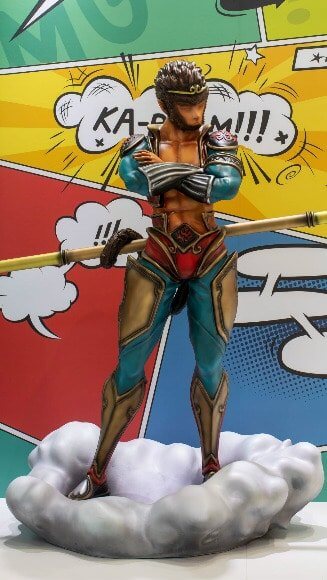

Monkey King 3D printed by Sid Installation Art in 64 hours.

Monkey King 3D printed by Sid Installation Art in 64 hours.Massivit 3D owners rave about the speed increase they get when using a 3D printer, and the huge impact it has made on their business. One of them is Media Resources co-owner, Steve Gallow, who has clearly been won over. His company conducted a direct comparison of CNC vs 3D printing, to astonishing results.

“A 3-foot model of Batman took us 14 hours to make on our CNC machine and had to be created in 2 parts, while the same model on the Massivit 1800 took 6 hours and only one part,” Gallow explained. “For me, that meant that the Massivit 1800 provides a much lower cost for overall production. And of course, the machine obviously shaves months of production time off hand carving.” As the old adage goes, time is money. It could also mean the difference between being able to take a job or having to refuse it because of a tight timeline. Fortunately, PSPs that own large format 3D printers no longer have to face this conundrum. “This is a real game changer for us and importantly means that we’re no longer having to turn business away,” explains Eric Pessarossi, general manager at Deko 3D.

No Axis 3D Printing vs CNC

Who needs axis when you can print exactly what you want from scratch? While CNC routers have evolved from 3 axis to 5 axis, these types of limitations are almost completely obliterated when it comes to large format 3D printing. The geometry freedom of 3D printers allows for ultra-complex creations. This opens the door for true creative freedom, where the only limitation is the imagination.

It’s something that has completely opened up what 3D fabricators and print services can do on applications such as props, scenic environments, selfie points, sports campaigns, window displays and custom mannequins.

For print services like the above-mentioned Deko 3D, it can make a big difference in terms of revenue. This Grenoble-based 3D bureau has been leveraging their Massivit printer to overcome the limitations of CNC machining. “We were unable to replicate our customers’ desired requirements, which unfortunately meant having to decline a number of lucrative projects,” Pessarossi admitted. “After several years of declining projects, largely due to the manufacturing constraints of CNC machining, we decided to create a dedicated division with in-house 3D solutions that could rectify this issue. Now, regardless of the scale and complexity of the application, we are able to meet our customers’ demands.”

Mind The Mess

There’s an inherent drawback in CNC manufacturing that simply can’t be swept under the rug. That’s because no rug is big enough to hide the astounding mess created during CNC milling. CNC is a subtractive process, which means you are taking away raw material to create something new. You need a lot more space to store your raw materials, but even more bothersome are the leftovers, which are messy and wasteful.

Large format 3D printing, on the other hand, is an additive process. You’re creating something from the ground up, which means you don’t need storage space and there is no leftover mess to clean up. Large format 3D printers are also much easier to setup when compared to the complex configurations required for CNC milling. Simply feed the plans to the proprietary software, and watch it go.

The Verdict

While there is certainly a place for CNC machines in the 3D fabrication and printing arenas, it’s hard to ignore how far large format 3D printers have come. Comparing CNC vs 3D printing shows us how the latter has not only filled a gap of need, but has catapulted way beyond that. It’s no surprise that fabricators and print service providers are increasingly adding 3D printing to their arsenal. Whether it be with size, speed, complexity, or ease of use, large format 3D printers are creating new opportunities that have ultimately changed the market as a whole.

Top Image Credits from left: Carnero by Diego Licenblat, Motorbike by Massivit, and Star Wars X-Wing Magic Wheelchair by Dangling Carrot Creative and Monster City Studios