Company to Introduce a New Category of Additive Manufacturing, Enabling Production of Full-Scale Parts, Props, Sets, and Prototypes Within Hours

LOD, Israel, 16th November 2021 – Massivit 3D Printing Technologies (Tel Aviv Stock Exchange: MSVT), the leading provider of large-scale 3D printing systems will showcase the Massivit 5000 industrial-grade 3D printer at IAAPA, Orlando – Booth #2065, providing live demonstrations and exposing a wide range of experiential applications available for scenic fabricators.

IAAPA Visitors Can Book a Personal Meeting & Demo at the Massivit 3D Booth here

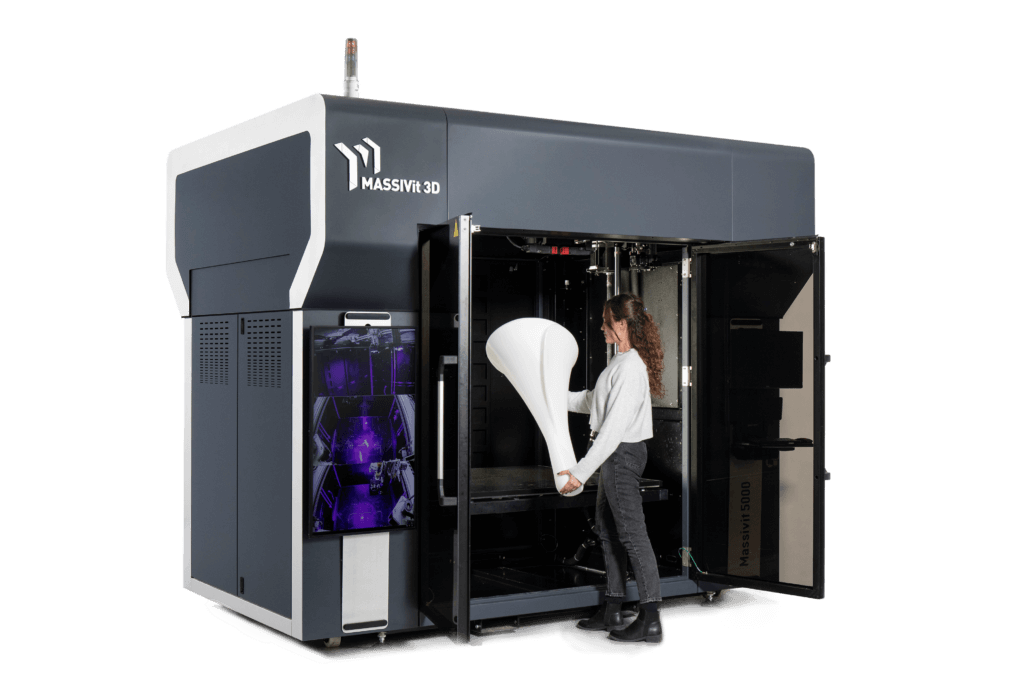

Marking a milestone for large-scale, creative construction, the Massivit 5000 3D printer was launched in 2021 and provides an exceptional build volume –

1450 x 1110 x 1800 mm – as well as a range of printing materials and layer thicknesses. It enables full-scale, complex parts to be digitally fabricated within a matter of hours, instead of days or weeks compared to conventional methods. The system also uniquely offers 2 print heads and the ability to print with a different material on each head for workflow efficiency.

Scenic fabricators have traditionally employed a range of manufacturing methods including manual sculpting as well as CNC milling processes – often posing limitations in speed, design complexity, and accuracy. Although 3D printers have entered the scenic fabrication arena, they are typically small-build printers that require long lead times due to their low printing speed and the need to remove support structures. The Massivit 5000 facilitates fast, digital, cost-effective production of full-scale, complex structures for a range of applications including experiential props, sets, prototypes, and molds. The technology is unique in its ability to produce hollow parts that require little-to-no support structures.

The high speed of the Massivit 5000 – up to 30 times that of existing 3D printers on the market – allows fabricators to focus their time and talents on creating elaborate finishes, interactive elements, animatronics, and other immersive entertainment elements. At Massivit 3D’s booth, IAAPA visitors will have the opportunity to watch live demonstrations of the Massivit 5000 throughout the event. On show will be a range of large-scale applications and projects by Massivit 3D customers – including immersive amusement park sets, event and exhibition displays, film and theater props, and custom gaming constructions. The Massivit 5000 is the latest of the company’s large-scale 3D printers to be introduced to market, leveraging the company’s patented Gel Dispensing Printing (GDP) technology. Based on advanced thermoset photo polymer materials and sophisticated slicing software, the Massivit 5000 enables parts to cure on-the-fly during printing, delivering ready-made parts straight off the printer.

“We’ve witnessed a snowballing momentum and adoption of our large-scale 3D printing systems over the past year by fabricators and service bureaus who are seeking a fast solution for producing large parts” commented Erez Zimerman, CEO at Massivit 3D. “Gel Dispensing Printing offers a new category in additive manufacturing that overcomes existing technological AM limitations related to speed and build volume. We’re thrilled to contribute this manufacturing milestone to the scenic fabrication arena.”

Download Press Release (PDF)

Download Pictures

Massivit 5000 Large-Scale 3D Printer

7 x 12 Foot football helmets for Cleveland Browns pre-game player runout 3D printed on Massivit 5000 by Water FX

Large-Scale 3D Printed Part – Massivit 5000

Statue of David Replica 3D Printed by AdSpaceMKT on Massivit 1800

About Massivit 3D

Massivit 3D Printing Technologies Ltd. www.massivit3D.com (Tel Aviv Stock Exchange: MSVT) is the leading provider of large-scale 3D printing systems for the Transportation, Architecture, Scenic Fabrication, and additional industries. Massivit 3D’s solutions enable ultra-fast, cost-effective production of large parts, paving a new category in additive manufacturing. The company’s patented Gel Dispensing Printing technology leverages advanced thermoset photo polymer materials and sophisticated slicing software to facilitate production of ready-made parts straight off the printer. Founded in 2013, Massivit 3D is headquartered in Lod, Israel and provides its customers across 40 countries with end-to-end services, supported via an extensive global dealer network.

MASSIVIT 3D MEDIA CONTACTS:

Aviv Sax-Nahamoni

Marketing Director

Phone: +972-8-6519486

Fax: +972-8-6900758

Email: [email protected]

Kevin Sykes

President, North America

Phone: +1 770 330 1000

Email: [email protected]