Lod, Israel, 4th November 2021 –

Massivit 3D Printing Technologies Ltd. www.massivit3D.com (Tel Aviv Stock Exchange: MSVT), the leading provider of large-scale 3D printing systems, has announced it will introduce the industrial-grade Massivit 5000 large-scale 3D printing system at Formnext 2021 this month in Frankfurt, Germany, as well as new groundbreaking additive manufacturing tooling technology for composite materials.

Visitors to Formnext can pre-book a demo or personal meeting with Massivit 3D here.

Visitors to the Massivit 3D stand (Hall 12.1 Booth #C119) will experience live demos of large-scale, complex parts – each 3D printed within a number of hours – throughout the event. A wide range of applications will be showcased, from full-scale printed railway parts to automotive design and wide body kits, and custom furniture.

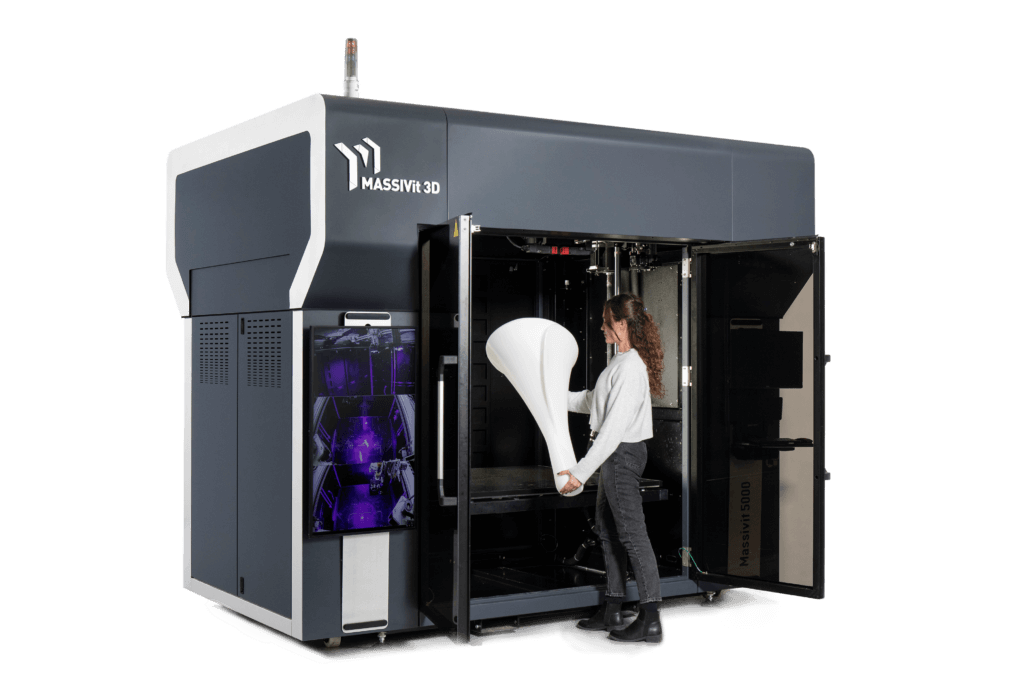

The Massivit 5000, launched in 2021, is designed to expedite manufacturing of large parts, prototypes, and tooling for the automotive, marine, rail, architecture, defense, and additional industries. Offering an exceptional build volume of 145cm x 111cm x 180cm (57” x 44” x 70”) and up to 30 times the printing speed of other 3D printers on the market, the Massivit 5000 introduces a new category in additive manufacturing, responding to recognized limitations in AM production speed and size.

The Massivit 5000 offers a range of layer thicknesses, print modes, advanced materials, sophisticated slicing capabilities, and cutting-edge computer vision features designed to provide both flexibility and enhanced workflow efficiency. One of the system’s highlights is a Dual Material System that allows operators to print simultaneously with a different material on each print head.

Based on the company’s patented Gel Dispensing Printing (GDP) technology – already adopted across 40 countries – the Massivit 5000 facilitates production of large, complex parts and models that instantly cure during the printing process, enabling ready-made parts straight off the printer with almost no required support structures.

At the stand, visitors will also have the opportunity to explore the new, award-winning Massivit 10000 – a revolutionary tooling system for composite materials, due to be launched in 2022. Recently announced at CAMX 2021 (Dallas, TX) as the winner of the prestigious ACE Award for Composites Excellence in the category of Manufacturing, the Massivit 10000 is designed to overcome the bottlenecks of mold production for composites manufacturing by automating the process. It serves multiple FRP arenas such as marine, automotive, railway, consumer goods, and sporting goods. Aiming to replace conventional molding processes that are slow, expensive and dependent on skilled labor, the Massivit 10000 shortens mold production time by 80%, reduces manufacturing costs by 75%, and decreases the need for high-skilled manual labor by 90%.

Leveraging a patented thermoset additive manufacturing technology called Cast-In-Motion, the Massivit 10000 facilitates direct printing of industrial-grade molds within a water-breakable outer shell, allowing molds to be produced within a matter of days, instead of weeks. It leverages advanced, thermoset polymer casting materials that provide a high HDT (Heat Deflection Temperature) and low CTE (Coefficient of Thermal Expansion).

The Massivit 10000 will be available at the Formnext event for limited-time pre-orders via a rapidly growing waiting list. The company will also unveil two new 3D printing materials at Formnext, thereby expanding the available applications available to its customers. DIMENGEL 20-FR (Dim 20-FR) is a novel flame-retardant 3D printing material – compliant with the UL94-V0 standard – that will enable customers across many industries to meet essential flammability-related safety and performance requirements. DIMENGEL 300 (Dim 300) is a rigid, translucent material, ideal for production of large translucent prototype housings, design verification, device covers, illuminated body parts, functional testing of translucent parts, concept models, interior design elements, and a range of advertising applications.

“The additive manufacturing arena has long awaited a technological breakthrough regarding production speed, scale, cost effectiveness, and material versatility” commented Erez Zimerman – CEO at Massivit 3D. We are excited to showcase our latest large-scale 3D printing systems at Formnext and to demonstrate the transformative nature of these innovations for the manufacturing market at large. Massivit 3D is addressing the dire need for large-scale additive manufacturing – capable of producing parts within hours, instead of days or weeks.”

About Massivit 3D Printing Technologies

Massivit 3D Printing Technologies Ltd. massivit3D.com (Tel Aviv Stock Exchange: MSVT) is the leading provider of large-scale 3D printing systems for a range of industries including Automotive, Marine, Rail, Architecture, Scenic Fabrication, and more. The company was established with a vision to overcome existing limitations in production speed, size, and material versatility associated with additive manufacturing. Massivit 3D’s portfolio of 3D printing systems leverage unique thermoset polymer technology to enable fast and cost-effective production of large parts. The company develops and manufactures unique, proprietary hardware, advanced thermoset polymer materials, and sophisticated integrated software. Founded in 2013, Massivit 3D is headquartered in Lod, Israel and successfully completed its initial public offering (IPO) on the Tel Aviv Stock Exchange (TASE) in Q1, 2021. The company provides its customers across 40 countries with end-to-end services, supported via an extensive global dealer network.

Download Massivit Logos

Download Press Release PDF

Massivit 10000 and Massivit 5000 pictures

©ALSTOM. Tramway cabin front-end panel 3D printed by Stratiforme Industries.

Massivit 5000 Large-Scale 3D Printer

Massivit 10000 AM Tooling System

Custom Stern 3D Printed by Velum Nautica for Composite Materials

MASSIVIT 3D MEDIA CONTACTS:

Aviv Sax-Nahamoni

Marketing Director

Massivit 3D

Phone: +972-8-6519486

Fax: +972-8-6900758

Email: [email protected]