Blog

Home > Blog

BLOG

Discover the advanced developments and latest applications in additive manufacturing industry trends by exploring our blog.

The advent of 3D printing ushered in a new era of possibilities in the evolving realm of manufacturing. When exploring industrial 3D printers and their potential to impact your business, the excitement is tangible. However, amid this excitement, navigating the intricate landscape of technical specifications becomes crucial. This guide aims to empower you, guiding you the choices and assisting you in selecting the right industrial large format 3D printer for your business needs.

In the world of recreational vehicles (RVs), customization is key. Whether catering to luxury travelers, digital nomads, or adventurous souls, RV manufacturers are constantly seeking innovative ways to meet the diverse needs of their customers. Enter 3D printing, a revolutionary technology that is reshaping the way RVs are designed, produced, and enjoyed across all segments of the market.

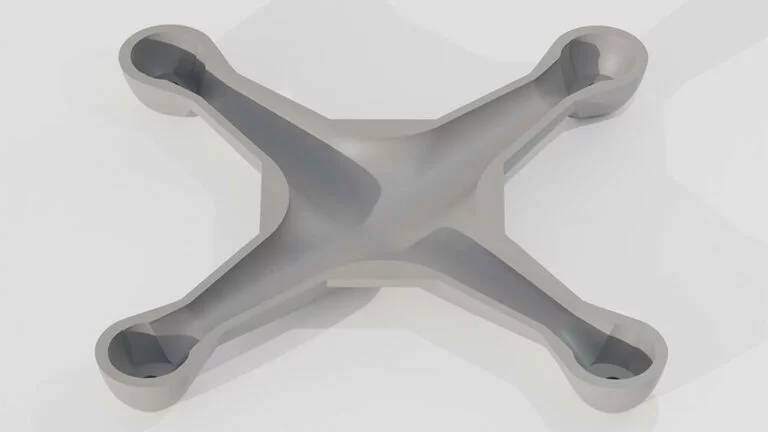

There is a remarkable increase in the prevalence of drones (according to Gartner) and they’re not just employed for military purposes.

The marine industry is poised for significant growth, particularly in ship and boat building and repairing, reaching $284.22 billion in 2023. Projections indicate a further increase to $303.65 billion in 2024, reflecting a compound annual growth rate (CAGR) of 6.8 percent.

The pursuit of more advanced vessels has driven innovation in boat building, leading to the development of a range of new manufacturing techniques, alternative construction methods, and materials. These groundbreaking advancements are shaping the future of the industry, paving the way for the efficient creation of elegant yachts, ships, catamarans, and vessels that navigate the world’s oceans.

At the forefront of boatbuilding innovation are advanced materials that push the boundaries of performance and design. Following our first blog exploring commonly used boatbuilding materials, we delve into more advanced materials, their unique properties and their transformative impact on boat construction.

The evolution of boat-building techniques is a testament to human ingenuity and the relentless pursuit of better ways to navigate the world’s oceans. From the humble dugout canoe to the sleek carbon fiber racing yacht, each advancement has pushed the boundaries of what is possible. Over centuries, boat construction has undergone a remarkable transformation, evolving from rudimentary crafts made from natural materials to sophisticated vessels incorporating the latest technological advancements. This 3-part boatbuilding blog delves into the latest techniques and materials boat builders use for contemporary boat manufacturing.

Imagine reducing production timelines, slashing inventory costs, and creating complex components with ease. These are just a few opportunities the aerospace industry can unlock with the power of large-scale 3D printing technology.

The automotive industry has always been at the forefront of material innovation. From the early days of steel and aluminum to today’s modern materials, it’s a sector that never stops evolving.

Quando si pensa al processo di costruzione di un’imbarcazione, una stampante è l’ultimo strumento che viene in mente di utilizzare. Tuttavia, la rapida innovazione della stampa 3D rende sempre più necessario disporre di una stampante 3D per far fronte alla concorrenza, alla domanda e per mantenere costi competitivi.

The aftershocks of recent supply chain disruptions still ripple through global industries, prompting manufacturers to rethink their strategies. As companies grapple with the fallout, one thing is clear: adaptability is paramount. Enter the era of industrial robots and workfloor automation, solutions that promise to buffer the effects of these disruptions, thereby ensuring manufacturing continuity.

In this article, we will delve deeper into the relationship between Industry 4.0 and additive manufacturing and explore how this technology is driving innovation and sustainability in the manufacturing sector. We’ll also discuss the role of academia-industry partnerships in advancing additive manufacturing, the impact of this technology on key industries, and the challenges and opportunities that lie ahead.

No more posts to show