As we head into 2023, we’ve seen a lot of change already. Additive manufacturing has grown by leaps and bounds, revolutionizing the processes of production, all while reducing its carbon footprint. In this article, we explore how 3D printing is driving sustainability efforts across industries and changing the way we think about production. From reducing material waste and transportation emissions, to enabling the use of sustainable materials and increasing energy efficiency, there are many ways in which additive manufacturing is making a positive impact on the environment. Let’s take a look at this game-changing technology, starting with newly released research findings.

Sculpteo Releases State of 3D Printing Report

One of the informative market barometers we’ve come to rely on for 3D printing market trends is the Sculpteo. The Sculpteo State of 3D Printing Report. This annual analysis of the 3D printing industry gathers data via a survey of engineers, CEOs, designers, and researchers from Europe and North America. The report highlights key trends and issues related to the adoption, use, and future of 3D printing technology. This year, we can derive some crucial statistics on the industry’s push for more sustainable manufacturing processes

Some of the most interesting findings from the report include:

- 61% of respondents agreed that 3D printing’s main benefit is on-demand production, which helps eliminate the cost and waste associated with overproduction.

- 41% of respondents agreed that 3D printing is helping them meet their sustainability goals.

- 63% of respondents said they are looking for ways to reuse scrap parts.

- 40% of respondents said they use 3D printing for short series production runs, and 18% use it for mass production.

- 40% of respondents said they desire more sustainable manufacturing methods and materials.

- 84% of respondents said they are optimistic about the future of 3D printing, with 58% being “very optimistic” about its role in the wider world of manufacturing.

- 35% of respondents said they need greater support to get the most out of 3D printing, and 35% said they need more specialized materials.

- 31% of respondents agreed that software advances could unlock further applications for 3D printing.

“This year, we decided to highlight a major issue of concern to all sectors of industry, and something we see as a major challenge ourselves: sustainability,” said Alexandre D’Orsetti, CEO of Sculpteo. “I’m delighted to say that this technology has a very bright future, and proud to be able to make my own contribution to the future of 3D printing.”

Overall, these findings suggest that 3D printing is increasingly being recognized as a valuable tool in manufacturing, with a wide range of applications and the potential to contribute to more sustainable production practices. Additionally, the report suggests that there is strong optimism about the future of 3D printing, with many respondents seeing it as an important technology for the future of manufacturing and for the long term goal of reversing climate change.

Looking ahead, we can expect to see continued innovation in 3D printing technology, with advances in materials, printing processes, and software likely to drive further adoption and expansion into new applications. In particular, the development of new and more sustainable materials, as well as the increasing use of 3D printing in production, are likely to be major areas of focus.

There are a number of industries that could be significantly impacted by new innovations in 3D printing technology. These include the automotive, aerospace, medical, and construction industries, which are already using 3D printing to produce a range of parts and components. As the technology becomes more widely adopted and the range of materials and applications expands, it is likely that other industries will also be impacted.

Massivit Making an Impact

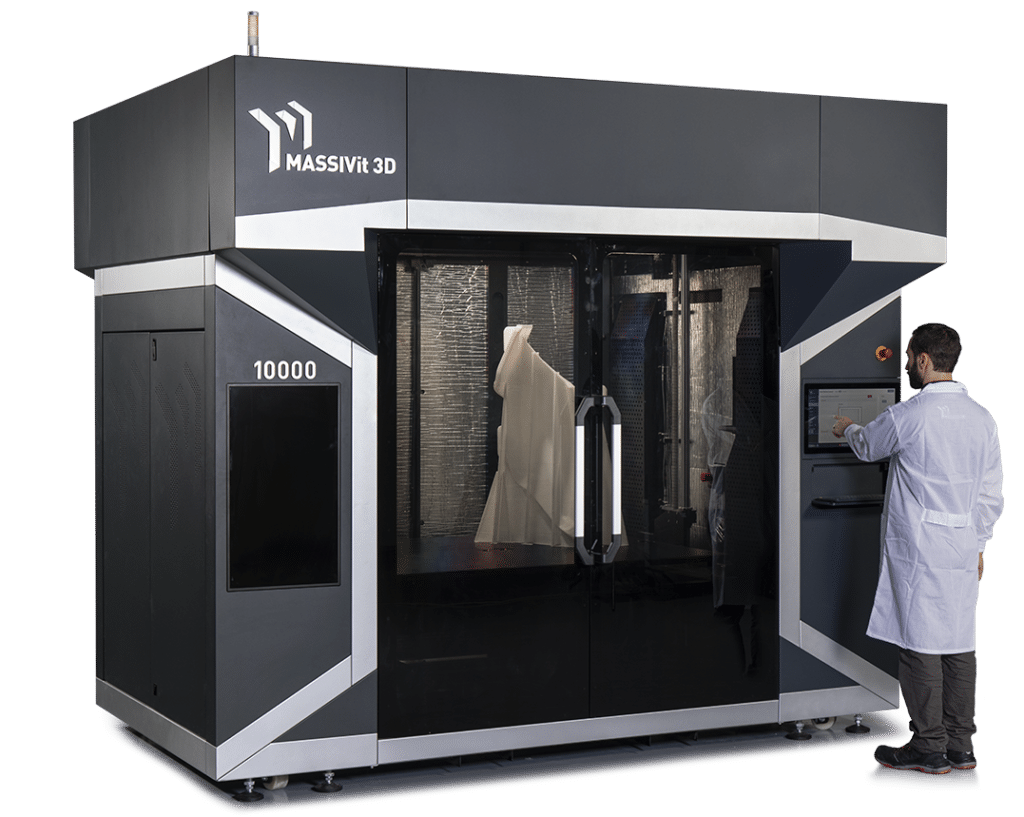

As a leading provider of large-scale 3D printing solutions, including the Massivit 5000, Massivit 10000, and Massivit 10000-G, we’re also out to make an impact.

That’s why we design our technology to be as sustainable as possible, from every angle:

- Massivit 3D printers produce hollow objects with almost no need for support structures, meaning that a significantly lower volume of raw materials is used and there is far less material waste generated.

- Like with many Additive Manufacturing technologies, Massivit 3D’s Gel Dispensing Printing technology almost solely makes use of necessary material, thus reducing waste, waste disposal costs and any associated carbon footprint. It enables on demand, onsite printing, that reduces manufacturing carbon footprint.

- The cured Dimengel material has no negative influence (such as soil pollution or ground water pollution) on the environment.

- The solidified (cured) thermoplastic printing materials used in Massivit 3D printers are classified as normal office waste and can be handled and disposed of in the same manner as many other regular plastic wastes via disposal bins for code #7 plastics.

In addition, implementing this kind of innovative technology means you can print parts on-demand, eliminating the need for large inventory warehouses, and their inherent carbon footprint – not to mention their costs.

Overall, Massivit technology can contribute to sustainable manufacturing by reducing material waste, increasing energy efficiency, and enabling re-use, customization, and on-demand production.

Of course, these printers also offer a range of advanced features and capabilities, such as ultra-fast printing speeds, the ability to print with a range of materials, and automated file preparation. The use of Massivit technology can bring significant benefits to manufacturers, including reduced production times, lower costs, and the ability to produce complex and customized parts on-demand.

We’re proud to be doing our part to encourage sustainable manufacturing through revolutionary technology. Additive manufacturing aligns perfectly with the global urgency of reducing our carbon footprint and creating a better world. It’s exciting to think how far the industry has come thus far, and fascinated to see the emerging trends and new advances that 2023 has in store.