Blog

Embracing technology in education is the way forward for attracting, engaging and retaining students at schools and universities. Some technologies, such as 3D printing, have been extremely effective, offering a variety of uses in schools, universities, libraries, among other educational institutions. Literacy in 3D printing, which is also called additive manufacturing, has become a valuable skill, as it aids teachers and professors in their ability to teach, adapt, and engage students.

Additive Manufacturing (AM) has become one of the most disruptive forces revolutionizing a vast range of diverse industries such as transportation engineering, architecture, medical technology, and even education. Manufacturing industries like automotive, rail, marine, and aerospace are among those that have seen a larger degree of AM integration into the production pipeline.

New technologies bring with them immense possibilities. Generally, these breakthroughs are directed at improving our lives in a real practical way. Technology can make us safe, more efficient, or, with increased automation, just give us more time to ponder the wonders of the world.

Over the past few decades, we’ve witnessed immense growth and technological maturation in 3D printing. Despite this progress, clear drawbacks remained. So when the innovators at Massivit set out to develop large-scale Additive Manufacturing (AM) systems that would outsize and outpace anything the competition could offer, the significance of these goals was never in question.

The art of creating set design, whether for a movie, TV show, or play, has always been a challenging one. Production designers and art directors for entertainment have large teams that go hunting for the perfect telephone or wardrobe to be featured on the set of your favorite movies and shows.

TPU filament is one of the most widely used flexible filaments on the market, with rubber-like material qualities that make it suitable for a wide range of applications, including 3D printing

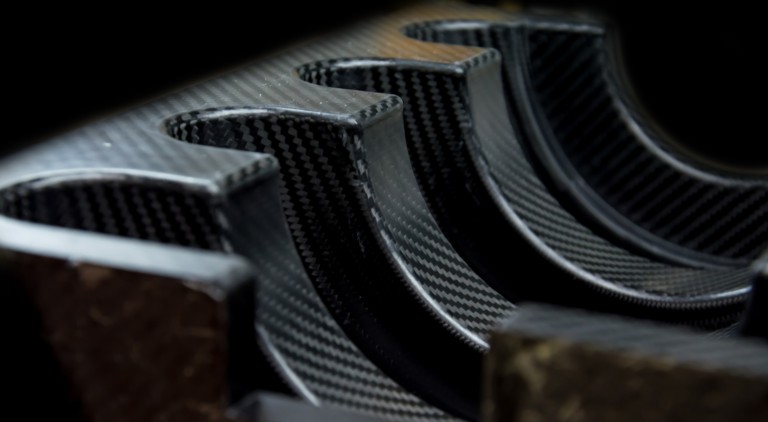

No matter which industry you are in, you may have noticed an increase in references to “composite materials” over the past few decades. Indeed, many recent manufacturing breakthroughs have been made possible due to these seemingly-futuristic compounds, which might imply that this is all new technology. Despite the major advancements in materials engineering, composite materials actually go back a long way.

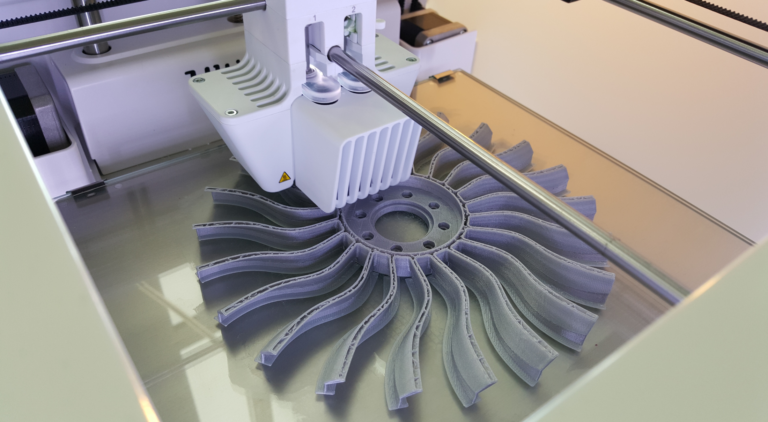

Prototyping is a critical phase of product development in which the designer or engineering team is primarily focused on validating the concept. The three pillars of prototyping are form, fit, and function and any or all of these need to be tested for a given product or component to gain valuable user feedback.

Last month we wrote about 3D printing software at scale. It’s a worthy read in its own right, and a valuable precursor to this next topic. Today we’ll address how different 3D printing software can fit into each and every workflow stage.

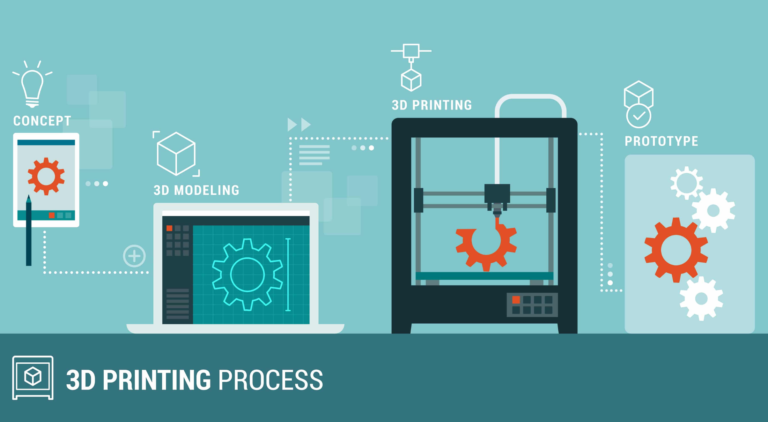

If you’re using or considering Additive Manufacturing (AM), you know the technology allows for more quickly produced, lighter, higher-performing, or better-optimized parts. You probably know as well that 3D printing is a multi-step process, and that having a design and printer doesn’t mean that a final part is just one mouse click away.

Casting has a history that harkens back to the bronze age. In fact, the first recorded use of casting to create an object was in 3200 B.C. when a frog made of copper was created in Mesopotamia. That began a long journey in the world of casting objects, starting with bronze tools and weapons, and on to ornaments, jewelry, and just about anything one can think of.

Motorized campers began to appear on the scene as early as 1910, and truly started coming into its own by the 1950s. Ever since Prohibition-era bootleggers in the U.S. retuned their cars’ engines to be more powerful in order to evade law enforcement, people have been engaged in a passionate love affair with customizing our motorized vehicles.

No more posts to show