Large 3D Printers

Home > Large 3D Printers

A NEW LEAGUE IN HIGH-SPEED, ADDITIVE MANUFACTURING

Massivit brings to market a portfolio of groundbreaking, large scale 3D printers that are transforming manufacturing across 40 countries in a range of industries including automotive, marine, rail, consumer goods, sporting goods, and scenic fabrication. Produce full-scale, custom production parts, industrial molds, or functional prototypes within hours. Massivit’s large format 3D printers are based on two innovative technologies, Gel Dispensing Printing and Cast In Motion, that dramatically streamline manufacturing workflows, reduce costs, and minimize material waste.

MASSIVIT 10000 SERIES

A game changer for composite materials manufacturing, the Massivit 10000 automates mold production and tooling, allowing you to directly print industrial molds based on any geometry within days, instead of weeks.

MASSIVIT 5000 SERIES

The Massivit 5000 delivers a new league in large scale 3D printing, enabling manufacturers to print full-scale custom end parts and functional prototypes at 30 times the speed of other 3D printers.

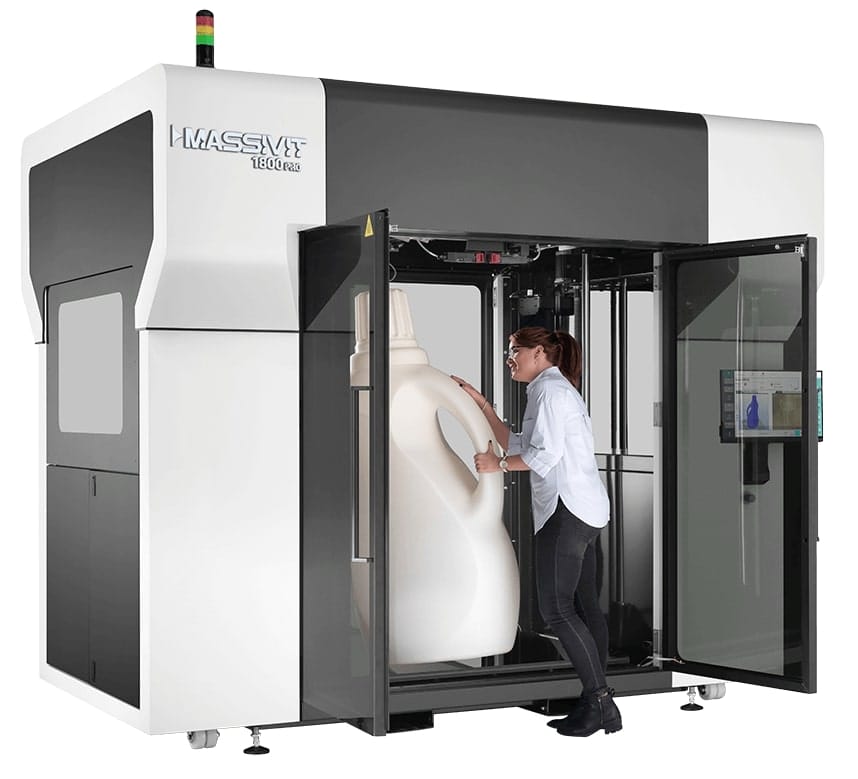

MASSIVIT 1800 SERIES

The Massivit 1800 offers high-speed production of large, complex parts, mockups, and displays allowing you to meet tight turnovers, simplify your production workflow, and gain a competitive edge.